Industry Spotlight: How AI Is Transforming Logistics

AI transforms logistics by optimising operations and revolutionising decision-making. Predictive analytics anticipate demand shifts, while autonomous vehicles enhance efficiency and safety. Smart warehouses utilise advanced systems for inventory management and space optimisation. Robotics streamline tasks and boost productivity. Real-time monitoring improves inventory tracking and operational efficiency. Enhanced route optimisation strategies reduce fuel consumption and boost fleet productivity. Data-driven customisation tailors services for specific customer needs. AI-driven logistics enhance customer journeys through personalised interactions. Explore the detailed ways AI is reshaping the industry.

Key Takeaways

- Predictive analytics optimise decision-making and resource allocation.

- Autonomous vehicles enhance logistics efficiency and safety.

- Smart warehousing maximises space and predicts demand fluctuations.

- Robotics streamline tasks, increase accuracy, and boost productivity.

- Real-time monitoring improves inventory tracking and operational efficiency.

AI-Powered Predictive Analytics

In the domain of logistics transformation, AI-powered predictive analytics revolutionises decision-making by forecasting future trends and optimising resource allocation. Predictive insights derived from vast amounts of data enable you to make data-driven decisions with precision and confidence. By harnessing the power of AI, logistics companies can now anticipate demand fluctuations, identify potential bottlenecks, and streamline operations for enhanced efficiency.

Through the utilisation of AI-powered predictive analytics, you can uncover hidden patterns within data that human analysis might overlook. These insights empower you to proactively address issues before they escalate, leading to smoother operations and improved customer satisfaction. By leveraging predictive analytics, you can allocate resources more effectively, reduce costs, and enhance overall performance.

Embracing AI-powered predictive analytics in logistics not only enhances operational efficiency but also provides a competitive edge in today’s fast-paced market. Utilising data-driven decisions backed by predictive insights allows you to stay ahead of the curve, adapt to changing circumstances, and drive success in the logistics industry.

Autonomous Vehicles in Delivery

Utilising autonomous vehicles for delivery operations introduces a pivotal shift in logistics efficiency and reliability. The integration of autonomous vehicles enhances vehicle safety by minimising human errors, reducing accidents, and ensuring adherence to traffic regulations.

These vehicles are equipped with advanced sensors, cameras, and artificial intelligence algorithms that enable them to navigate diverse road conditions with precision and caution, notably lowering the risk of collisions. Additionally, autonomous vehicles offer future scalability by allowing logistics companies to expand their delivery capabilities without the need for additional human drivers.

This scalability is vital in meeting the rising demands for fast and efficient deliveries in a world where e-commerce continues to flourish. As technology continues to advance, autonomous vehicles are poised to revolutionise the delivery landscape, offering a cost-effective and sustainable solution for logistics companies looking to optimise their operations.

Embracing autonomous vehicles not only enhances efficiency but also paves the way for a safer and more reliable delivery ecosystem.

Smart Warehousing Solutions

Implementing smart warehousing solutions revolutionises the efficiency and productivity of logistics operations by harnessing cutting-edge technologies. Automated inventory management systems are at the forefront of this transformation, allowing for real-time tracking and optimisation of stock levels. These systems utilise sensors, RFID tags, and barcode scanners to automate inventory processes, reducing vital error and streamlining operations.

Warehouse optimisation plays a vital role in smart warehousing solutions by maximising storage space and minimising unnecessary movements. Through the use of data analytics and machine learning algorithms, warehouses can intelligently organise inventory, predict demand fluctuations, and optimise picking routes. This results in reduced storage costs, faster order fulfilment, and improved overall efficiency.

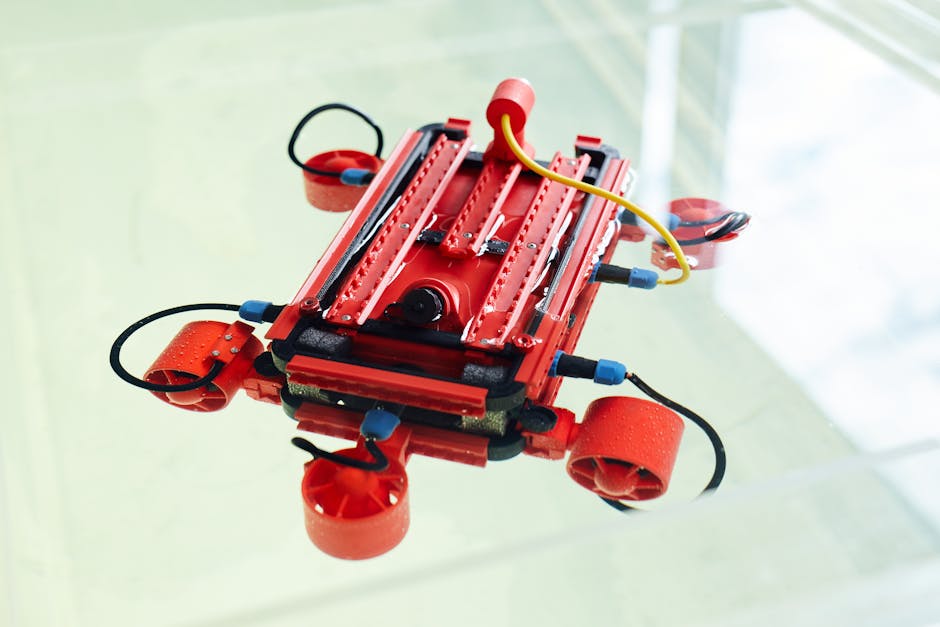

Robotics and Automation Integration

You can enhance operational efficiency in your logistics processes by integrating robotics and automation.

By leveraging robotics, you can streamline repetitive tasks and optimise resource allocation.

Automation brings about benefits such as increased accuracy, faster processing times, and improved overall productivity.

Efficiency Through Robotics

Efficiency is greatly enhanced in logistics operations through the seamless integration of robotics and automation. The robotics revolution has paved the way for operational excellence by streamlining tasks that were once labour-intensive.

Robotics in logistics offer precise control over repetitive processes, leading to increased accuracy and speed in operations. Automated systems can efficiently manage inventory, track shipments, and optimise warehouse layouts, contributing to a more streamlined supply chain.

Benefits of Automation

Enhancing operational performance, the integration of robotics and automation in logistics offers a myriad of benefits that streamline processes and optimise supply chain management. Increased productivity is a key advantage of automation in logistics. Robots and automated systems can work 24/7 without breaks, leading to faster task completion and enhanced efficiency.

This increased productivity translates into quicker order fulfilment and delivery times, ultimately improving customer satisfaction. Additionally, automation brings significant cost savings to logistics operations. By reducing the need for manual labour and minimising errors, companies can lower operational expenses and allocate resources more effectively.

Embracing robotics and automation not only boosts productivity but also drives profitability through streamlined processes and optimised workflows in the logistics industry.

Real-Time Supply Chain Monitoring

Implementing real-time supply chain monitoring systems allows companies to gain instantaneous insights into their logistics operations, enabling proactive decision-making and enhancing overall efficiency. By integrating technologies like RFID, IoT sensors, and AI algorithms, businesses can track inventory levels accurately and predict demand patterns with greater precision. This real-time visibility across the supply chain empowers organisations to optimise inventory management, reduce stockouts, and minimise excess stock, ultimately leading to cost savings and improved customer satisfaction.

| Real-Time Supply Chain Monitoring Benefits | Details |

|---|---|

| Enhanced Inventory Tracking | Track inventory levels accurately in real-time for better stock management. |

| Improved Demand Forecasting | Utilise data analytics to predict demand patterns and optimise inventory levels. |

| Proactive Issue Resolution | Quickly identify and address supply chain disruptions to prevent delays. |

| Increased Operational Efficiency | Streamline logistics processes and enhance overall supply chain performance. |

Enhanced Route Optimisation Strategies

Optimise your logistics operations by strategically refining route planning through innovative strategies for enhanced efficiency and cost-effectiveness. AI-driven efficiency plays a pivotal role in revolutionising route optimisation. By leveraging AI algorithms, businesses can analyse vast amounts of data to identify patterns, predict traffic conditions, and optimise delivery routes in real-time. Enhanced delivery routes are designed to minimise fuel consumption, reduce travel time, and improve overall fleet productivity.

AI’s ability to process complex variables such as traffic patterns, weather conditions, and delivery windows enables logistics companies to adapt dynamically to changing circumstances. This adaptability guarantees that routes are continuously optimised, leading to cost savings and improved service levels. Through AI-driven route optimisation, businesses can achieve greater accuracy in delivery time estimations, reduce the risk of delays, and enhance customer satisfaction.

Customer Experience Personalisation

Revolutionise your logistics operations by tailoring customer experiences through personalised interactions that enhance satisfaction and loyalty. By leveraging data-driven customisation and AI-driven recommendations, you can create a seamless and personalised journey for your customers.

Here’s how you can achieve customer experience personalisation:

-

Utilise Data Analytics: Gather and analyse customer data to understand preferences, behaviour, and trends, enabling you to offer personalised solutions.

-

Implement AI Recommendations: Use AI algorithms to provide tailored recommendations, improving the overall customer experience and increasing satisfaction.

-

Enhance Customer Interactions: Develop personalised interactions that prioritise the customer’s needs and preferences, fostering a customer-centric approach.

-

Drive Loyalty Through Customisation: By offering personalised services and solutions, you can build stronger relationships with customers, leading to increased loyalty and repeat business.

Incorporating data-driven strategies and AI technologies into your logistics operations can have a substantial impact on customer experience, setting you apart in a competitive market.

Frequently Asked Questions

How Do Ai-Powered Predictive Analytics Improve Forecasting Accuracy in Logistics Operations?

To improve forecasting accuracy in logistics operations, AI-powered predictive analytics utilise demand forecasting and machine learning algorithms. By analysing historical data, these tools can predict future demand more accurately.

Additionally, AI helps optimise routes and manage inventory efficiently. Machine learning algorithms continuously learn and adapt to new data, enhancing forecasting precision. This results in streamlined operations and better decision-making in logistics management.

What Are the Potential Challenges and Limitations of Implementing Autonomous Vehicles in Delivery Services?

When it comes to implementing autonomous vehicles in delivery services, you’ll face regulatory hurdles and safety concerns.

Envision this: moving through a maze where every turn has a potential obstacle. Regulatory hurdles, like varying laws across regions, can make the path challenging.

Safety concerns, such as ensuring the AI systems can handle unexpected situations, add complexity.

Overcoming these obstacles will require thorough planning and collaboration between industry stakeholders.

How Do Smart Warehousing Solutions Enhance Efficiency and Productivity in the Supply Chain?

Enhanced visibility and inventory optimisation are critical aspects of smart warehousing solutions. By leveraging AI technologies, warehouses can track inventory levels in real-time, anticipate demand fluctuations, and streamline order fulfilment processes. This enhances efficiency by reducing stockouts and overstock situations.

Additionally, smart warehousing solutions enable better resource allocation, minimising storage costs and maximising productivity throughout the supply chain. Overall, these advancements drive operational excellence and competitive advantage in logistics.

What Are the Key Benefits of Integrating Robotics and Automation Technologies in Logistics Processes?

When integrating robotics and automation in logistics processes, you can expect enhanced warehouse optimisation and streamlined inventory tracking. These technologies facilitate efficient order fulfilment, reduce human errors, and improve overall operational accuracy.

How Does Real-Time Supply Chain Monitoring Contribute to Better Decision-Making and Risk Management in Logistics Operations?

When you implement real-time supply chain monitoring, you gain a competitive edge through enhanced decision-making and risk management in logistics operations.

By leveraging real-time analytics and improving supply chain visibility, you can promptly identify issues, optimise routes, and mitigate disruptions.

This proactive approach enables you to make informed decisions swiftly, anticipate potential risks, and maintain a responsive and efficient logistics network.

Conclusion

As AI continues to revolutionise the logistics industry, it’s like having a well-oiled machine that can predict, adapt, and optimise at lightning speed.

Imagine a conductor leading a symphony orchestra with precision and harmony, ensuring each note is played at the perfect moment.

Just as AI orchestrates the logistics process seamlessly, transforming supply chains into efficient and customer-centric operations.

The future of logistics is here, and it’s powered by AI.

Contact us to discuss our services now!